The Many Ways Apps Are Transforming The Manufacturing Landscape

Today’s manufacturing landscape is vastly different to the landscape of the past. In the past, manufacturers had to rely on trial and error to improve their processes. In today’s data-rich environment, they’re able to make changes based on information. Right now there is a bevy of tools out there to help manufacturers get the most out of their operations. Here are some top picks.

The creators behind Visual Factory wanted to do something different with all the data now available to manufacturers. Instead of displaying it all in readouts, they wanted to streamline the process and make it visual. People, they reasoned, are much more able to process visual information than they are row upon row of figures. So the idea of the tool is to create visual cues that reduce the time it takes to understand factory information. These tools can then be used monitor equipment and improve communication. Visual Factory also allows users to condense all their operations into a single platform.

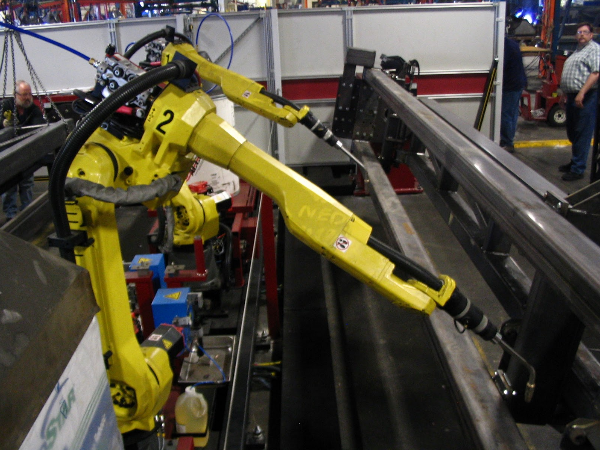

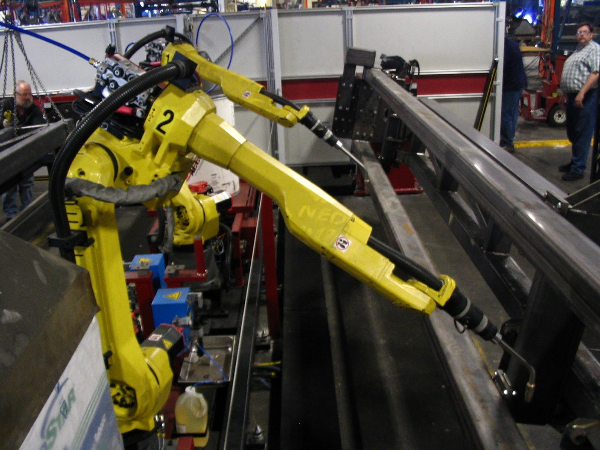

Manufacturing Automation

Modern manufacturing companies are automating their processes at an ever increasing rate. Now many are experimenting with end-to-end enterprise resource planning software. The idea behind this software is to collect all of the information from across the company into one platform. Firms use it to collect financial information, track orders and reduce overheads. Good enterprise resource planning tools include Syspro, Infor SyteLine, and Infor Visual.

Business Intelligence

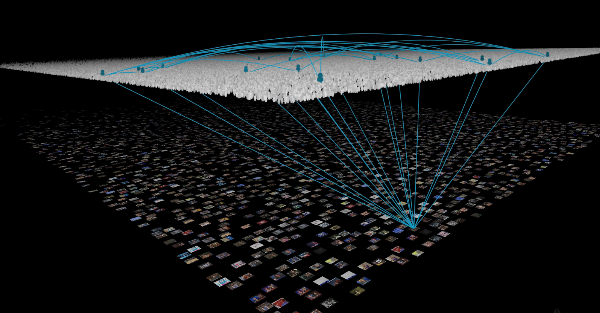

The information that manufacturers have at their fingertips is a resource. That’s why so many manufacturers are mining their data and trying to gain insights. With so many tools now collecting data, business intelligence is more feasible than ever before. Manufacturers can aggregate this data. And then they can use big data algorithms to gain valuable insights on how to business better. For instance, big data can be used to help manufacturers accurately measure lead times. Once they know the lead time, they are in a better negotiating position and can lock in prices. This, in turn, protects them from future variations in supply and demand.

When it comes to big data, the possibilities are practically endless. Manufacturers can collect data on the length of time it takes their customers to pay for instance. They can experiment with the way that they are charging customers to see if different billing mechanisms work better. Big data can also help manufacturers automate their expenditure tracking. This helps reduce administrative costs. And it opens up expenses to analysis, which may be able to reduce overhead even further. Business intelligence can also be used to measure risk. Before the advent of big data, it was hard to measure how risky certain operations were. But thanks to increases in processing power, risk is just as measurable as revenue.

Project Management

Keeping track of exactly what stage each of your manufacturing projects is at can be a challenge. That’s why many manufacturing startups use software to track their projects through time. Project management software, like PRINCE2, helps make your operations more consistent. It also allows businesses to regularly review the progress that they have made and make sure projects are justified. Like many business applications, project management programs often come with a steep learning curve. Most companies opt for some kind of training before investing in such a package. See it at Simplilearn for more information.

Maintenance Software

Keeping track of all your maintenance issues can be time-consuming, especially if you run a large operation. You need to employ staff who will churn out spreadsheets and charts detailing when maintenance is due. And you need to pay people to walk around with clipboards, checking off various pieces of equipment. It can all get rather expensive. A much cheaper, and probably safer option is to use maintenance software. These software packages keep track of useful information, like how long a machine has been in operation. They are also designed to keep you informed when a machine needs repairs and how to increase the accuracy of your reporting. When paired with other systems, these can sync with accounting programs and keep your business integrated.

And what about all those people who used to do clerical work? Well, you can put them to work doing things like spot checks and repairs. The labor savings are potentially enormous. Maintenance software packages include eMaint, NetFacilities, and Maintenance Connection.

Accounting Software

Accounting software packages have been around for a long time now, just like project management packages. But that doesn’t mean it’s any less important for manufacturing companies. Today’s accounting packages do much more than preparing the accounts. They automate transactional data from business bank accounts. They provide important reports and statistics on a company’s financials. And they can be used as a conduit through which customers do business. Things like card payments on invoices are now accepted as standard.

Some companies still use legacy packages. But if you’re starting up, it’s probably best to use new cloud-based apps. These apps can be accessed from any location. And they often end up being cheaper over the long run. Also, these apps chop and change, depending on the decisions of the tax authorities. If new rules come into force, they’ll quickly adapt so that you can correctly file your tax returns. When it comes to accounting software for manufacturers, there’s plenty to choose from. You can try out Quickbooks, Intacct or Freshbooks.

Manufacturing Dashboard Apps

Dashboard apps have been a successful additional to many businesses over the last few years. And they’re starting to make a significant impact in the manufacturing world. Dashboard apps are closely related to business intelligence systems. The idea is to bring all your key performance indicators into one place so that you can make decisions. Dashboards provide information on sales, operations, and oversight. And they help avoid many of the productivity-draining aspects of running a factory. Getting people together in a room to update each other on their status can be time-consuming.

There are many dashboard apps on offer, including Board, iDashboard and PBL Scorecard.

Comments

There are 0 comments on this post