5 Common Types Of Machinery Used In Manufacturing Industries

Manufacturing businesses rely on their equipment and infrastructure to produce products in mass quantities. Usually, these machines automate the production process or specific steps within the process. As a business owner, you should always be on the lookout for better tools to streamline your production and improve your budget. Investing in the right machinery could lead to lower costs and increased capacity for your business. To learn more about what other companies are doing across several industries, here are different types of machinery used in manufacturing.

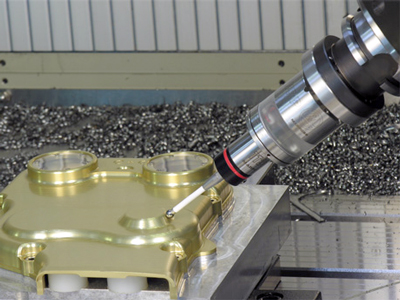

CNC Machine Tools

A computerized numerical control (CNC) machine tool performs automated functions to cut materials. Using computer programmed sequences, CNC machines can create unique sizes and shapes of products. These machines are highly effective for creating metal parts or products. In a materials supply business, the machine tools are critical to manufacturing quality parts. With the precision of computing power, you can rest assured that human errors are mitigated greatly. Moreover, the automation and productivity of these tools can keep costs low. Once you have the machine running in place, you can produce metal parts in large quantities. These machines are some of the most popular in manufacturing companies.

Laser Cutting Tools

Next, the use of laser cutters allow manufacturers to create various products. Since laser cutters come with a high upfront cost, they are not common place for small businesses. However, the companies buy or rent equipment for cutting materials can see their return on investment very quickly. Depending on the type of product that you wish to produce, a laser cutter can maximize the use of materials. If you are manufacturing wooden products, a laser cutting tool can provide top notch precision for your products without producing too much waste. Obviously, if you can make the post out of your materials, your business will earn a higher margin on its products. Of course, this is a wise choice for material-sensitive manufacturing businesses.

Injecting Molding Machines

For plastic products, manufacturers turn to injection molding machines. These machines heat up materials and inject the liquid into a mold that has the shape of a part or product. You would need to invest in the machine itself as well as the mold for the product as both can get costly. Additionally, you could consider buying used injection molding machines to lower the costs. Once the equipment and materials are secured, these machines can run on a high level of automation. For the most part, products produced are ready to go, requiring very little additional work. If you’re business produces plastic products in bulk, you should consider making the upgrade to injection molding machines.

Loom Weaving Machine

Similarly, the garment industry relies on looms. These are weaving machines that string together fabric using warp and weft. They fully automate the weaving process, using pressured air or water to intertwine thread together. As a garment manufacturer, this machinery creates a consistent product for consumers. A loom can control the feel and look of fabric. If your business manufactures garments, it would be a savvy decision to acquire looms for specific products. You can create various types of fabric with a single loom. As you can imagine, a loom can produce thousands of yards of fabric to earn profits over its use-life.

3D Printing Machines

Most recently, companies are investing in 3D printers to quickly produce prototypes. This is one of the most innovative machines for research and development. It allows businesses to take ideas to product form in very little time. Moreover, you can leverage the power of 3D printers to produce your own products. Depending on the type of 3D printer, you can use various materials and control the consistency of output. If you are interested in producing lot of different products, a 3D printing machine is a good place to start. As 3D printers continue to become more robust, manufacturing companies will rely on them more for their main production activities.

These are some of the most popular types of machines used in the manufacturing sector. In order to be successful in business, you need the latest tools and equipment available. You should invest in CNC machines for metals parts and products. For materials that need to be cut, you can buy laser cutters that have a high level of precision. Then, you can make your own plastic products with injection mold machines. If you would like to get into fabrics, then a loom could provide a major return for the business. Finally, for a wide range of products, a 3D printer can produce many products for manufacturing purposes

Comments

There are 0 comments on this post